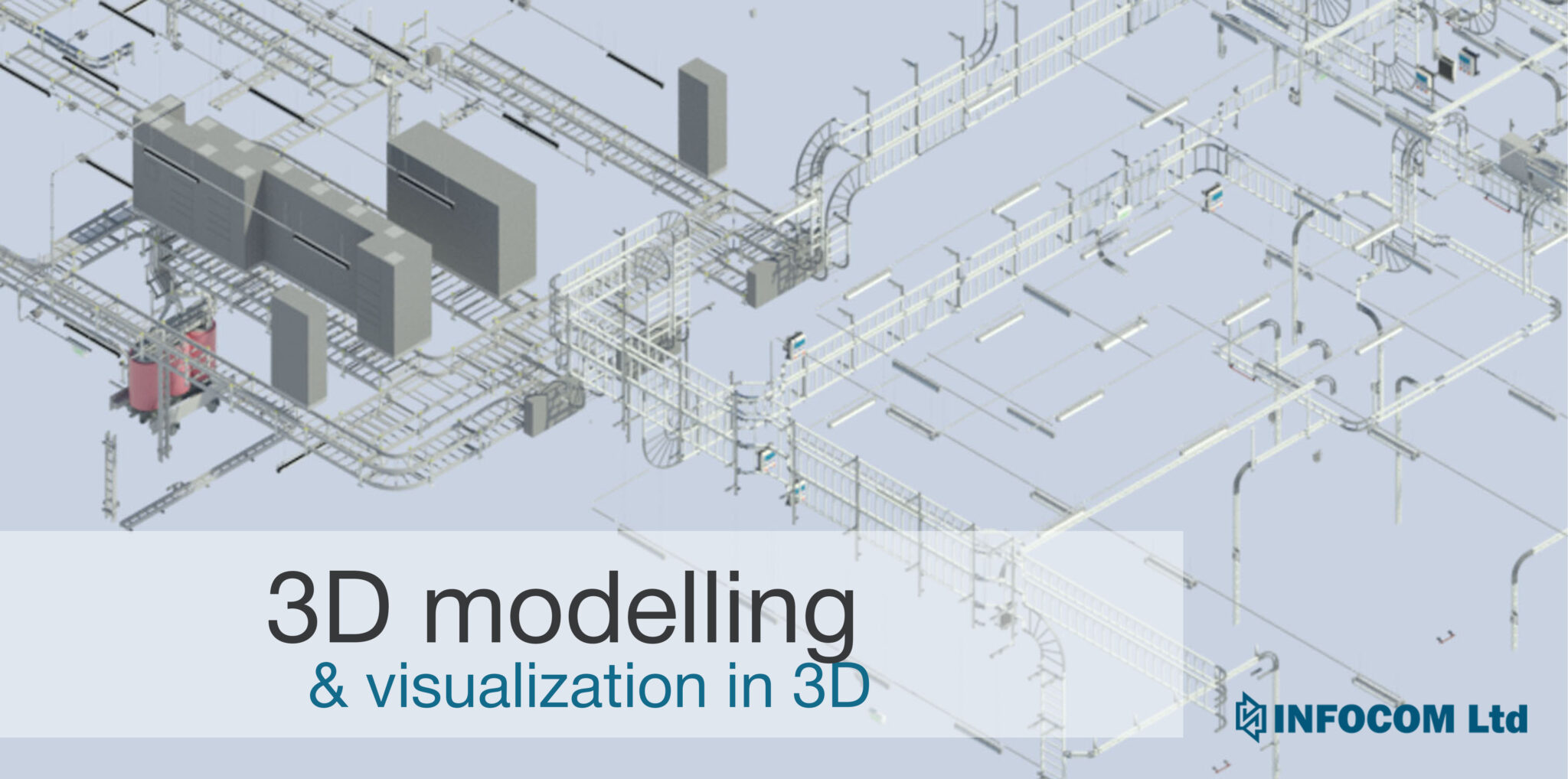

3D modeling and visualization in the development of automation and power supply projects (EAI)

In the design of production facilities, as in any other type of design, the coordination of different parts of the project is the subject of discussions, long-lasting meetings and worst of all, sometimes lost time for correcting issues. That is why our customers are ordering more and more frequently the development of a 3D model in advance when designing new production facilities. Based on 3D model the coordination of all interconnected systems are coordinated.

Skills of INFOCOM LTD in 3D models design and 3D visualization

- 3D equipment allocation;

- Coordination with interconnected systems (water supply, compressed air, firefighting, ventilation, technological equipment, etc.)

- Design in 3D of non-standard solutions for the installation of special equipment (cabinet frames, raised floors, wall/floor mounts, brackets, etc.);

- 3D plans of automation equipment location;

- Preparation of preliminary technical specifications for the construction of premises based on 3D modeling (construction requirements);

- Building an ideology of 3D cable route placement;

- 3D placement of related systems (lighting, ventilation, air conditioning);

- Ideology of 3D placement of non-standard equipment (containers, non-standard products, etc.)

Benefits for companies that order 3D modelling:

Bill of materials optimization

Subcontractor’s work orchestration

Reduced rewiring costs

Reduce communication intersections

Materials optimizations

Realistic estimations