- Unmanned transport system

- Transport system

- Infrastucture of unmanned vehicle control

- Hybrobus

- Portable solar systems, mounted on the hybrid car chassis

- Cargo drones

- Vehicle management

- Autonomous loading/unloading

- Autonomous drilling and drilling robots

- Scalable solutions for mines and excavations

- Robot Guide - your «teleport» to anywhere in the world

- Unmanned automobile Jeep

- Jeep special equipment

- UGV control system description

- Unmanned transport complex

- Additional equipment

- Smart Glove

- Smart Glove functions description

- Unmanned technology for the agricultural sector

- Mobile app "UGV Driver Assistant"

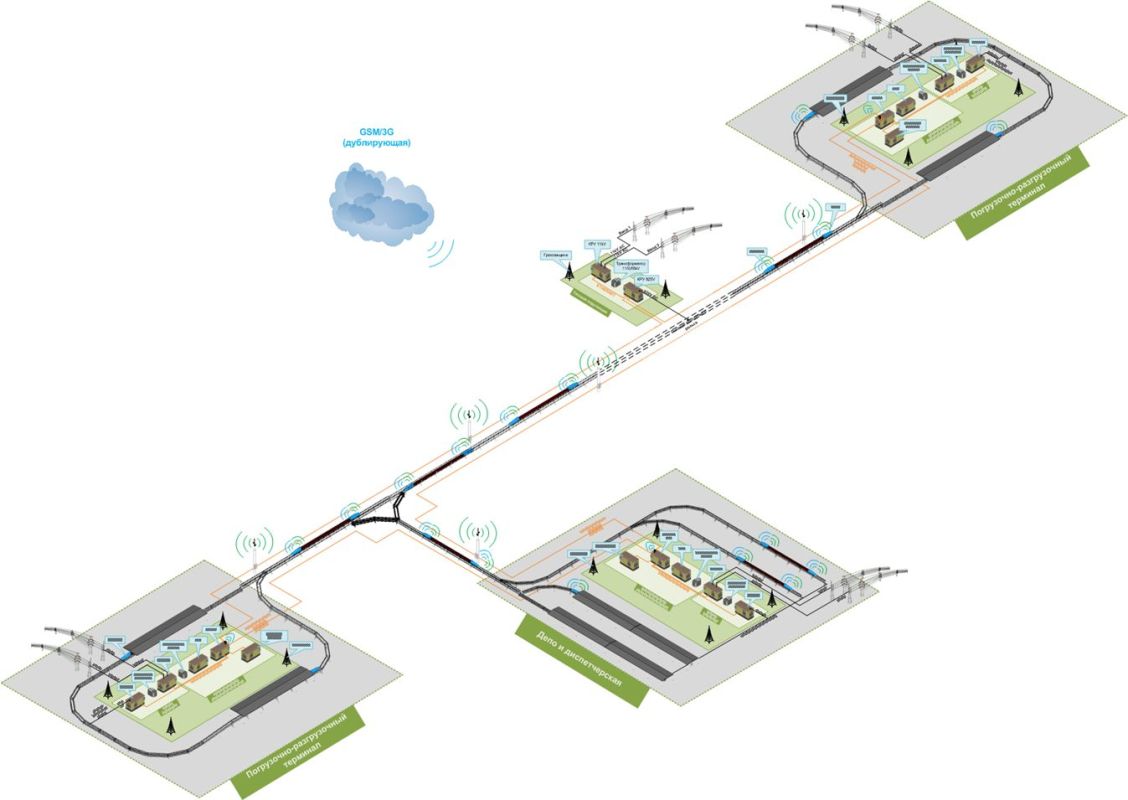

Transport system consists of:

- rolling stock (special configuration train);

- railway track structure; – control systems;

- power supply system;

- cargo-handling terminals;

- depot.

Transport system key features:

- type – cargo;

- railway track system – double-level double-track trestle system

- cargo transportation distance, km, max – 31;

- height of span placing above ground level – 0 to 10 m.;

- maximal operating speed of train traffic – 25 (90) m/s (km/ h);

- trains traffic interval – from 400 to 650 s.;

- locomotive type- electric locomotive;

- railroad gauge, – 1000 mm;

- number of trains – 8-16 items.

Dispatching system key features:

- automatic maintenance of performance schedule;

- review of standard time-schedule;

- automatic route determination on train performance sheet;

- review of the performed train sheets over any period;

- print of standard and performed time-sheets;

- documentation of transportation of every consignment (train number, product type, quantity, loading and unloading dates) with the data transfer to SAP ERP;

- tracking of direct expenses of resources for the transportation of every consignment with the data transfer to SAP ERP;

- tracking of the overhead expenses of resources for the infrastructure maintenance with the data transfer to SAP ERP.

MRO (Maintenance, Repair and Overhaul) system key features:

- preventive maintenance;

- cyclical and acyclic maintenance plans;

- automatic warning about the technological service (with the notification of dispatcher);

- manual review of the serviceable equipment under any criterion;

- standard work package, including spare parts, equipment and skills.